Company News

A solar bracket system typically consists of components such as columns, main beams, purlins, welding parts, and foundations. Currently, there are three main types of solar bracket systems based on the materials used: concrete mounts, steel mounts, and aluminum alloy mounts. The choice of materials for the mounting system usually depends on the climate. For instance, in coastal areas, all structural components should be made of galvanized steel or aluminum due to their high corrosion resistance. Among these, aluminum alloy mounts are popular in the PV market due to their lightweight, corrosion resistance, and ease of installation.

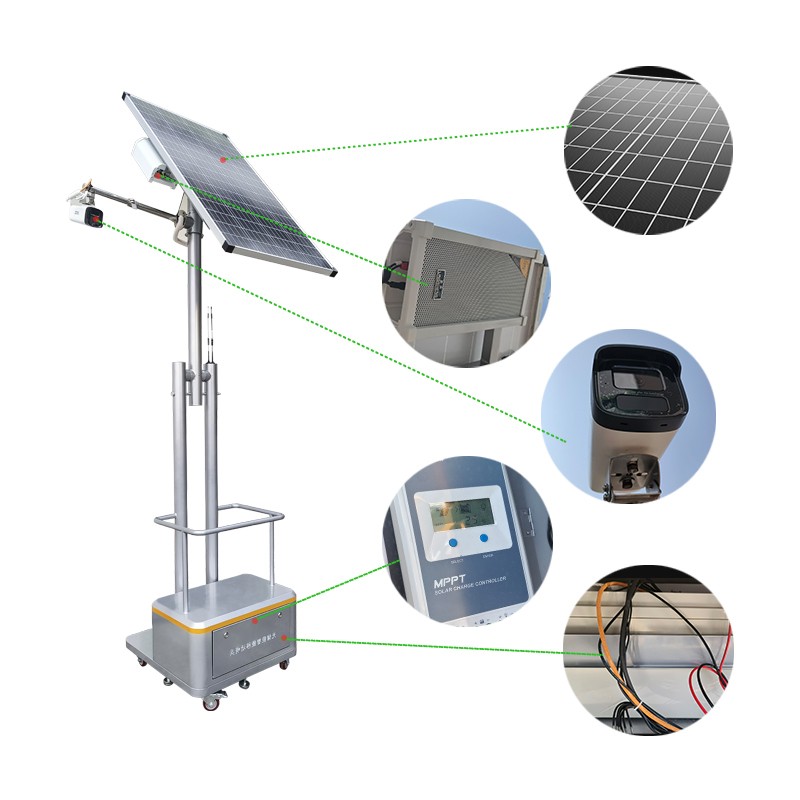

Depending on whether the mounting angle can be freely adjusted later, mounting systems are classified into fixed mounts and tracking mounts. Fixed mounts can be further divided into regular fixed mounts and adjustable fixed mounts, while tracking mounts can be categorized into single-axis tracking mounts and dual-axis tracking mounts. In China, fixed mounts dominate the market, while tracking mounts are more widely used in overseas markets.

1. Classification of Solar Bracket System Based on Installation Surface and Application Scenarios:

Ground Mounting System:

- Installed on the ground, typically used for large-scale PV power stations or distributed generation projects.

- Ground mounting systems can be fixed or adjustable to allow for tilt angle changes in tracking systems.

Rooftop Mounting System:

- Installed on building rooftops, such as sloped roofs, flat roofs, or other types of rooftops.

- Rooftop systems must consider factors such as the building structure, load-bearing capacity, and waterproofing.

Facade Mounting System:

- Installed on building facades, integrated with the building's walls, often seen in Building Integrated Photovoltaics (BIPV) systems.

Floating Mounting System:

- Installed on water surfaces, commonly used for floating PV power stations on reservoirs, lakes, and oceans.

2. Application Scenarios:

Ground Mounting System:

- Suitable for large-scale PV power stations, industrial parks, agricultural greenhouses, and other areas with ample land space.

- Commonly used in projects requiring large-scale solar panel installations to generate significant power.

Rooftop Mounting System:

- Ideal for rooftops of commercial buildings, industrial plants, schools, warehouses, etc.

- Maximizes the use of rooftop space to provide clean energy for the building.

Facade Mounting System:

- Applicable to tall buildings, cultural buildings, office buildings, and other large-facade structures.

- Integrates solar panels into building facades, providing clean energy while enhancing the aesthetic appearance of the building.

Floating Mounting System:

- Suitable for large water surfaces, such as reservoirs, lakes, and oceans.

- Utilizes water surface space for PV power generation, reducing land occupation and minimizing water evaporation.

3. Performance Comparison of Mounting Systems:

Load Capacity:

- Ground mounting systems typically need to support high wind and snow loads, while rooftop systems must account for the roof's load-bearing capacity and waterproofing.

Installation Cost:

- Ground mounting systems are relatively easier to install but require consideration of foundational work and land preparation costs.

- Rooftop mounting systems involve additional costs due to roof structure considerations and waterproofing measures.

Adjustability of PV Panel Tilt Angle:

- Adjustable ground systems can optimize panel angles based on seasonal changes and sun height to enhance power generation efficiency.

Aesthetics:

- Rooftop and facade systems focus more on aesthetics to match the building’s appearance, while ground systems are less restricted by visual requirements.

Maintenance Cost:

- Maintenance costs include regular cleaning, inspection, and repair. Ground systems may have relatively lower maintenance costs.

In conclusion, different types of solar bracket system are suitable for various scenarios, each with its unique characteristics and advantages. Choosing the right mounting system requires careful consideration of the project's specific conditions, cost-effectiveness, and long-term maintenance needs.